The Ultimate Guide to Solar Cell with Jackery

Whether the source is sunshine or artificial light, solar cells are referred to as photovoltaic. They serve as photodetector devices, such as infrared detectors, that can detect light or other electromagnetic radiation close to the visible range or measure light intensity. Solar cells are frequently grouped to create solar modules, which are then connected to solar panels, which are even larger units.

Some solar-powered gadgets don't even have an off button and never require batteries. They operate indefinitely as long as there is sufficient sunlight. But how does solar energy use? Of course, the solar cell plays a part. You will discover what a solar cell is, how it functions, how it was developed, and how to choose the best solar panel with Jackery in this post.

What is A Solar Cell

The solar cell is a crucial component of photovoltaic energy conversion, which transforms light energy into electrical energy. Semiconductors are typically utilized as the material for solar cells. Converting energy entails charge carrier separation and the production of electron-hole pairs in a semiconductor from light's photon energy absorption.

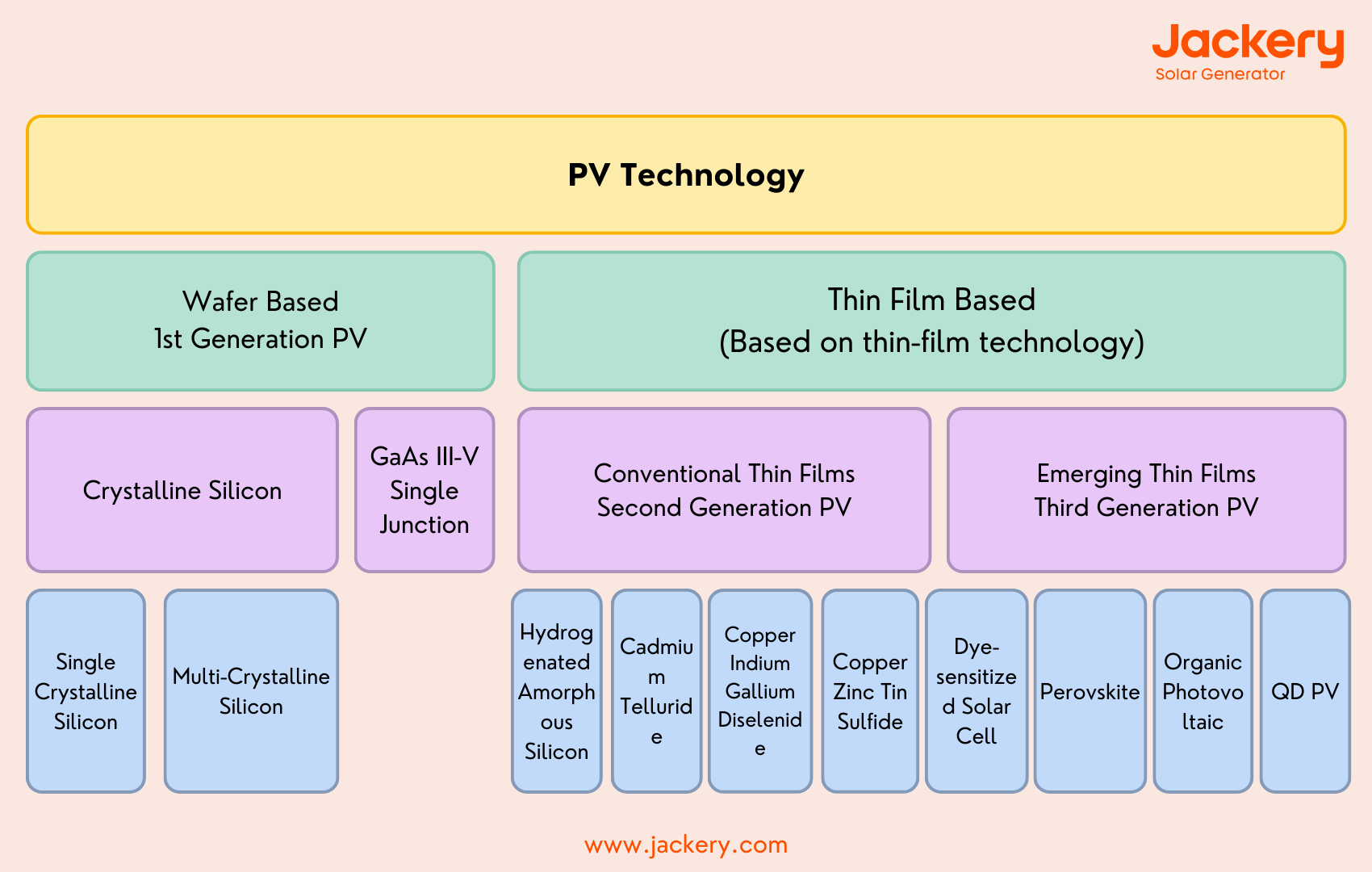

French scientist Edmond Becquerel initially showed the photovoltaic phenomenon in 1839. Based on fabrication methods, solar or photovoltaic technology can be divided into three generations. First-generation solar cells are constructed using silicon, which is both efficient and profitable. The original generation of silicon-based solar cells still accounts for 80% of today's solar cell production. The first generation consists of monocrystalline silicon solar cells, polycrystalline, amorphous, and hybrid.

Source: Anthony Fernandez

What is Solar Photovoltaic Cell?

A photovoltaic (PV) cell, also known as a solar cell, can either reflect, absorb, or pass through a light that strikes it. The semiconductor material that makes up the PVPV cell can conduct electricity more effectively than an insulator but is less effective than a good conductor like a metal. In PVPV cells, a variety of semiconductor materials are employed.

When a semiconductor is exposed to light, the light's energy is absorbed and transferred to the semiconductor's negatively charged electrons. The additional energy enables the electrons to conduct an electrical current through the material. This current can be used to power your home and the rest of the electric grid by extracting it through conductive metal contacts, which are the grid-like lines on solar cells.

How is The Solar Cell Market Today?

The efficiency of solar cells has increased dramatically in recent years, going from reports of roughly 3% in 2009 to over 25% presently. Although solar cells have rapidly increased their efficiency, several obstacles must be overcome before they can be considered viable commercial technology.

Wafer-based PV and thin-film cell PVsPVs are the two primary divisions of photovoltaic technologies. The wafer-based PVsPVs include conventional crystalline silicon cells and gallium arsenide cells, with c-Si cells currently controlling the PVPV market with a market share of roughly 90% and GaAs having the highest efficiency.

What Are Solar Cells Made of

A layer of p-type silicon is sandwiched between a layer of n-type silicon to form a solar cell. There are too many electrons in the n-type layer and too many positively charged holes in the p-type layer. The electrons on one side of the junction (n-type layer) migrate into the holes on the opposite side, which is close to the intersection of the two layers (p-type layer). As a result, a region known as the depletion zone is formed surrounding the connection, where the electrons fill the holes.

The p-type side of the depletion zone now contains negatively charged ions, and the n-type side of the depletion zone now includes positively charged ions when all the holes in the depletion zone have been filled with electrons. These ions' opposite charges provide an internal electric field that inhibits the n-type layer's electrons from filling the p-type layer's holes.

- Purify the Silicon: Silicon dioxide is put in an electric arc furnace, where oxygen is released using a carbon arc. Carbon dioxide and molten silicon are left, but even this is not pure enough to be used in solar cells. This silicon will produce one with just 1% impurities.

- Create Single Crystal Silicon: The Czochralski Method, in which a seed silicon crystal is dipped into molten polycrystalline silicon, is the most used technique for producing single-crystal silicon.

- Cut the Wafers: A circular saw is used to slice the second-stage boule into silicon wafers. The best raw material for this task is diamond, which produces silicon slices that can then be further cut to create squares or hexagons that are simpler to slot together into the surface of a solar cell.

- Doping: This technique, also known as doping, often entails firing phosphorous ions into the ingot using a particle accelerator.

- Add Electrical Contacts: Electrical contacts serve as a conduit for the current generated by solar cells and connect them. These connections, made of metals like palladium or copper, are thin so as not to prevent sunlight from reaching the cell..

- Add Anti-Reflective Coating: To lessen the quantity of sunlight lost through reflection, an anti-reflective coating is put on the silicon.

- Encapsulate the Cell: To complete the process, the solar cells are sealed in silicon rubber or ethylene vinyl acetate and mounted in an aluminum frame with a glass or plastic cover for added protection and a back sheet.

Source: US Energy Information Administration

How Does A Solar Cell Work

The solar cell is a technological innovation that directly converts light energy into electricity through the photovoltaic effect, creating electrical charges free to travel through semiconductors. All solar cells share a similar fundamental design. An optical coating or antireflection layer that reduces the quantity of light lost through reflection allows light to enter the system. As a result, the light is trapped and is more likely to reach the layers below that do energy conversion. Spin-coating or vacuum deposition creates this top antireflection layer, commonly an oxide of silicon, tantalum, or titanium.

Below the top antireflection layer are three energy conversion layers. These are the top junction layer, the absorber layer, and the back junction layer. Two additional electrical contact layers carry the electric current to an external load and then back to the cell to complete the electric circuit. A solar cell is a sandwich of n-type silicon and p-type silicon. It generates electricity by using sunlight to make electrons hop across the junction between the different flavors of silicon:

- Photons (light particles) pelt the cell's upper surface when sunlight shines.

- The photons (yellow blobs) transport energy through the cell at a downward angle.

- In the lower p-type layer, photons transfer their energy to electrons (green blobs).

- With the help of this energy, the electrons can penetrate the barrier into the top n-type layer and break out into the circuit.

- As the electrons move across the circuit, the lamp begins to glow.

Source: Advanced Renewable Energy Systems

The Types of Solar Cells

The three main categories of solar cells are crystalline silicon-based, thin-film solar cells, and a more recent innovation that combines the other two. P-type and n-type silicon are two types of semiconductors used to make solar cells. Atoms with one fewer electron in their outer energy level than silicon, like boron or gallium, are added to create p-type silicon.

Crystalline Silicon Cells

Crystalline silicon (c-Si) wafers, cut from massive ingots manufactured in laboratories, make about 90% of solar cells. These nuggets can develop into single or numerous crystals and can take up to a month to grow. Monocrystalline solar panels are made from a single crystal, whereas polycrystalline are made from multiple crystals.

Thin Film Solar Cells

While thin-film solar cells, also known as thin-film photovoltaics, are around 100 times thinner than crystalline silicon cells, they are still produced from wafers that are only a tiny fraction of a millimeter deep (about 200 micrometers, or 200m). Amorphous silicon (a-Si), in which the atoms are randomly organized rather than in an ordered crystalline structure, is the material used to create these thin film solar panels and cells. These films can also be produced using organic photovoltaic (PVPV) materials, copper indium gallium diselenide (CIGS), and cadmium-telluride (Cd-Te).

Third Generation of Solar Cells

The most recent solar cell technologies combine the best aspects of thin-film and crystalline silicon solar cells to deliver high efficiency and enhanced usability. They frequently have several junctions made up of various semiconducting materials' layers. Also, they are typically made of amorphous silicon, organic polymers, or perovskite crystals.

Solar Cell Development

Solar energy already offers consumers many advantages while reducing the harmful environmental effects of fossil fuel power generation. Switching to solar energy has benefits on a more local level and reduces air pollution and carbon dioxide emissions because it locates power generation at the point of use.

Smaller devices like watches and calculators may now operate without batteries, and road and train maintenance signs can now be powered by the sun so that they can be used in even the most remote regions. In some nations, solar energy is used to power telephone booths, water pumps, and even refrigeration systems in medical facilities. As the supply of fossil fuels declines, there will be a greater need to turn to renewable energy sources, such as solar.

Best Portable Solar Panels with Jackery

Jackery portable solar panels can be folded and strapped for easy carrying and use. One of the highest efficiency rates in the industry makes it possible to maximize the sun's energy and transform it into clean energy. Use solar power and the Jackery rechargeable portable power stations to keep your equipment charged. For better backup power, it is the advanced off-grid solar generating system.

With mono crystalline solar cells and adjustable supports, Jackery portable solar panels have a charging efficiency of up to 25%. Make the most of solar energy's potential. The solar panel can be easily connected to your power source. Connect the DCDC input of your portable power source to the DCDC interface.

Jackery SolarSaga 100W Solar Panel

The Jackery SolarSaga 100W solar panel is the best option for unplanned power disruptions. It is also ideal for outdoor enthusiasts due to its collapsible, lightweight, and easy-carry handle. The monocrystalline silicon solar cells and multi-layered cell technology enable the solar panels' higher conversion efficiency of 24.3%, which improves performance. The Jackery Explorer 300/500/1000/1500 power station is compatible with this solar panel, making it the perfect choice for off-grid camping and unplanned power outages.

|

Product |

Compatible With |

Recharging Time |

Conversion Efficiency |

Kickstands |

Specialty |

|

Jackery SolarSaga 100W |

Explorer 1500 Pro + 2*SolarSaga 100 |

4H |

23% |

2 kickstands |

- It weighs only 10.33 lbs - The TPE rubber handle - 1* USB-C output, 1* USB-A output |

|

Explorer 1000 + 2*SolarSaga 100 |

8H |

||||

|

Explorer 500/300/240 + 1*SolarSaga 100 |

9.5/5/4H |

Jackery SolarSaga 80W Solar Panel

Both sides of the dual-sided Jackery SolarSaga 80W panels may produce electricity. The back panel's extra-white glass increases conversion rates. It can survive challenging conditions because it is certified as dustproof and waterproof to the IP68 standard.

|

Product |

Compatible With |

Recharging Time |

Conversion Efficiency |

Specialty |

|

Jackery SolarSaga 80W |

Explorer 240/300/500 + 1*SolarSaga 80 |

4/6/9H |

25% |

- IP68 Waterproof and Dustproof - 2-Meter Extension Cable - 2.8mm Low Iron Full Toughened Glass |

|

Explorer 1000 + 2*SolarSaga 80 |

9H |

|||

|

Explorer 1000 Pro + 2*SolarSaga 80 |

9H |

Solar Cell FAQs

The following are some frequently asked questions about the solar cells:

1. Are photovoltaic cells and solar panels the same?

They are not the same. Solar panels turn solar radiation into heat, whereas photovoltaic panels convert thermal energy into electricity. Because of this, these solutions are separate from one another. Instead, they might work better together.

2. What are solar energy, solar cells and solar panels?

An electrical component, a solar cell, produces electricity when exposed to photons or other light-related particles. A collection of photovoltaic cells arranged in a framework for installation makes up a solar panel. But since the dawn of civilization, people have been able to use the radiant light and heat from the sun by harnessing it through various ever-improving technology. Their relations are shown below.

3. What is the power rating of a single PV cell?

No matter how big they are, a single photovoltaic solar cell can generate an "Open Circuit Voltage" (VOC) of between 0.5 and 0.6 volts at 25°C (usually around 0.58V). This cell voltage stays reasonably consistent as long as there is enough irradiance light from dim to brilliant sunshine.

Final Thoughts

Solar cells use light from the sun to generate electricity. They go through the same manufacturing and processing steps as computer memory chips. The main component of solar cells is silicon, which absorbs the photons that the sun's beams emit. Jackery is devoted to producing the highest-quality solar panels as the solar cell industry develops. Making the most of the sun and converting it into clean energy is possible thanks to one of the sector's top 25% efficiency rates.

Disclaimer:

The runtime mentioned for appliances powered by Jackery is for reference only. Actual runtime may vary under different conditions. Please refer to real-world performance for accurate results.

![[Add-on] Jackery Manual Transfer Switch for Explorer 5000 Plus](http://ca.jackery.com/cdn/shop/files/add-on-jackery-manual-transfer-switch-for-5000-plus-240V.webp?v=1757043692&width=170)